Show Case: Beer Tap Handle

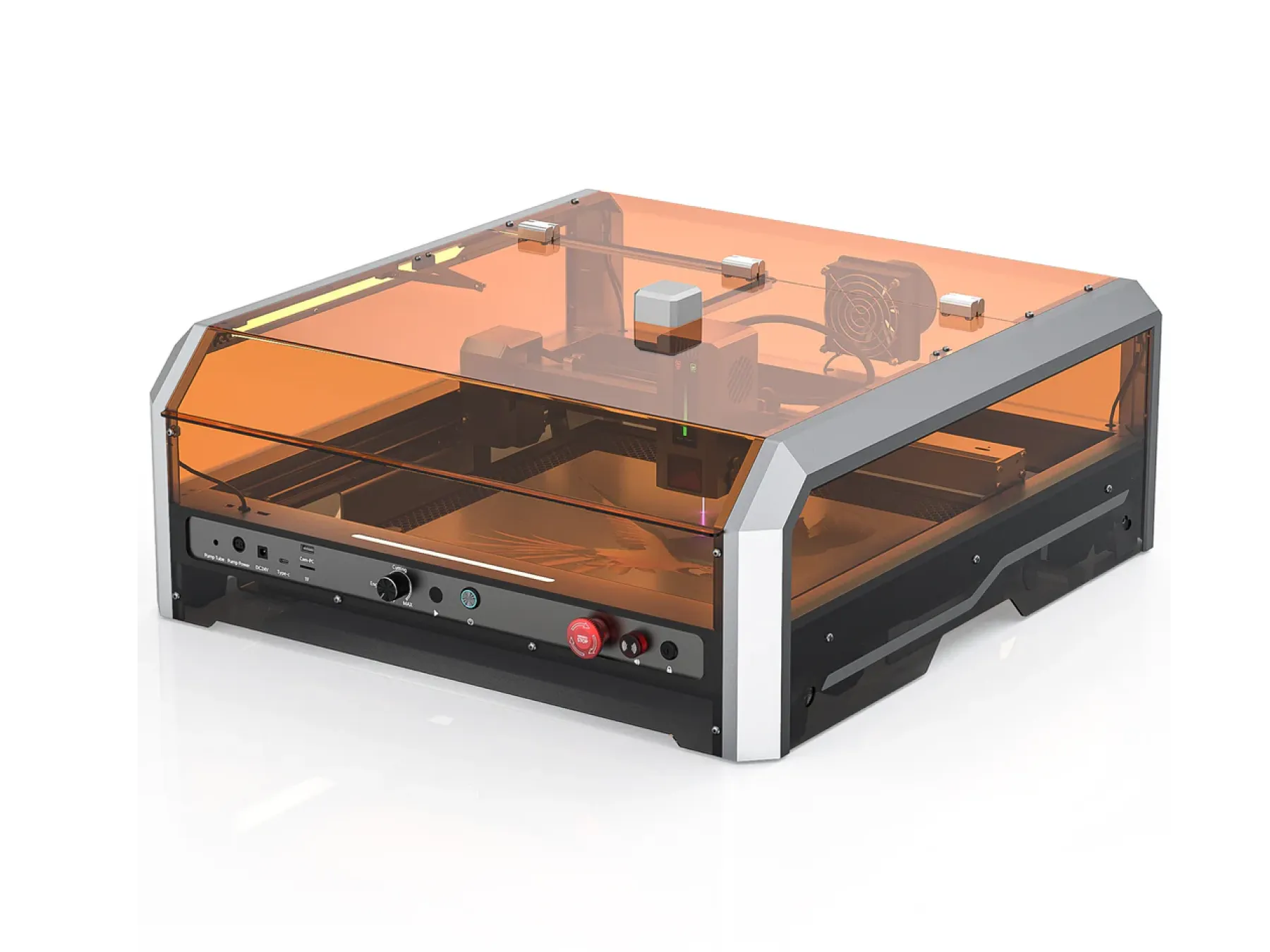

My son was moving into his first apartment after dorm life. He found a really clean keg refrigerator and tap that was missing the handle. He wanted his school logo on the tap handle and couldn't decide between v-carved Cherry or epoxy-filled maple. I made both, with the same 60deg v-bit and 3.125mm endmill at 2mm flat depth in 1x4 boards at 250mm long. Shellac was applied to the maple carve before the epoxy pour to prevent grain wicking. The epoxy was planed to a fraction of a mm proud with an endmill. Both handle sections were cut from the board after carving +/- epoxy & flattening with the provided SVG profile. There is plenty of room on the template to insert a logo of choice. (The school logo is proprietary to the institution.) The individual handle halves were laminated with glue & clamps. The bonded handle end was drilled with a 0.5"" forstner bit for a US beer standard 3/8-16 brass threaded insert. Then the handle was sanded in several steps to 220 grit, polished with a white nylon abrasive pad, and finished with 3 coats of a poly-tung oil wipe-on blend. I would love to try the engraving portion of this project with a laser. One with the capacity for deep engraving & vaporization rather than burning would be ideal.