From Maker Bench to Production Floor: How Desktop CNCs Are Powering the Next Wave of Rapid Prototyping

Share

Walk into any modern workshop and you’re likely to hear the hum of a compact CNC machine quietly shaping raw material into functional parts. Desktop CNCs, once the domain of hobbyists and tinkerers, are now being welcomed onto factory floors and engineering labs alike. Why? Because they offer the rare combination of affordability, precision, and speed — making them a natural fit for today’s fast-moving prototyping needs.

Rapid prototyping, long associated with 3D printing, is evolving. As product cycles shrink and demand for physical validation increases, accessible CNC technology is stepping up. The rise of desktop CNC machines isn’t just a maker trend — it’s a signal that the prototyping game has changed.

Rapid prototyping is a design and engineering process that involves quickly fabricating physical models from digital designs, often in iterative loops. Desktop CNCs play a vital role here by removing material (subtractive manufacturing), enabling engineers and designers to test, refine, and finalize components in-house — often within a single day.

What is a desktop CNC machine?

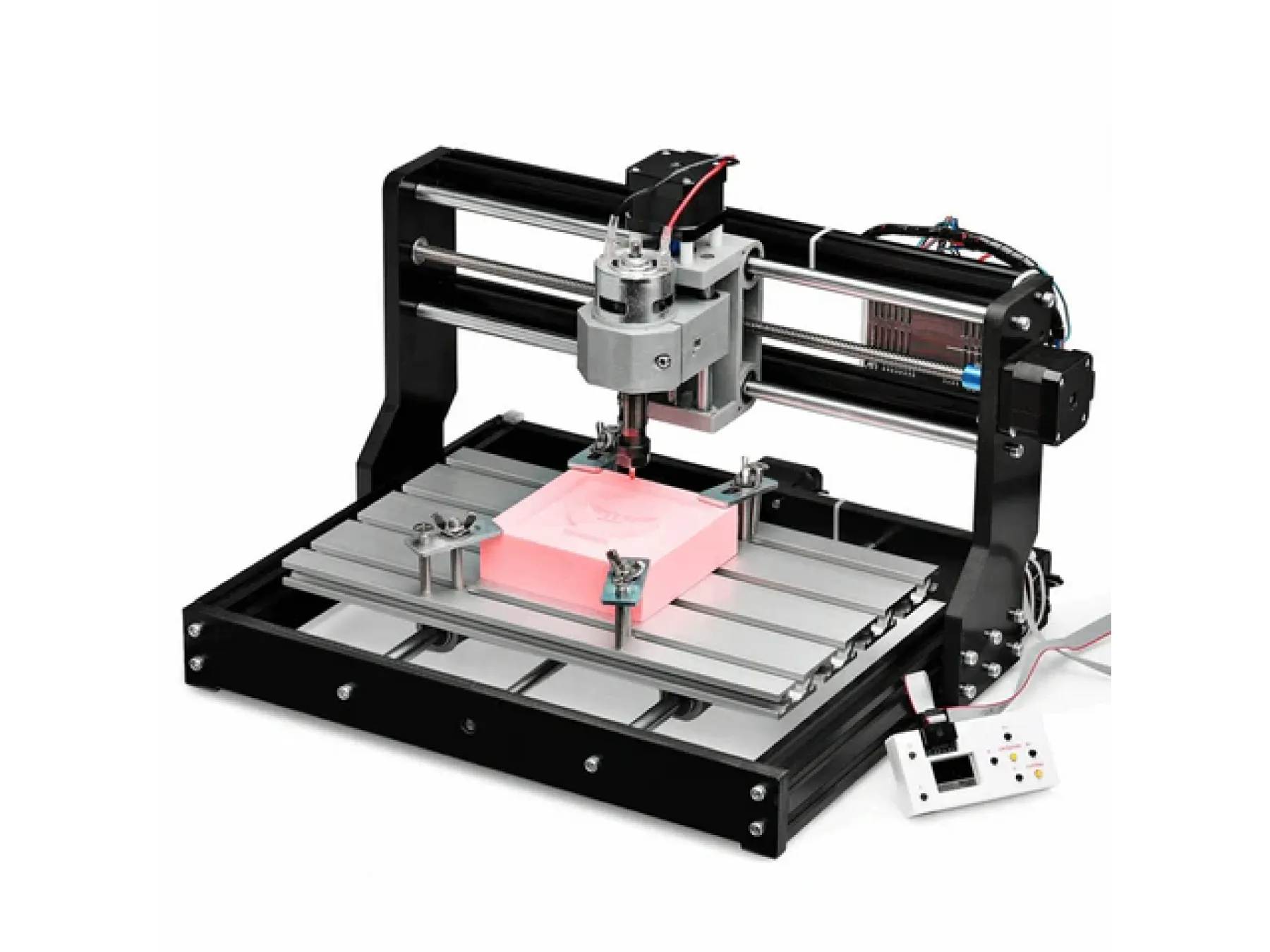

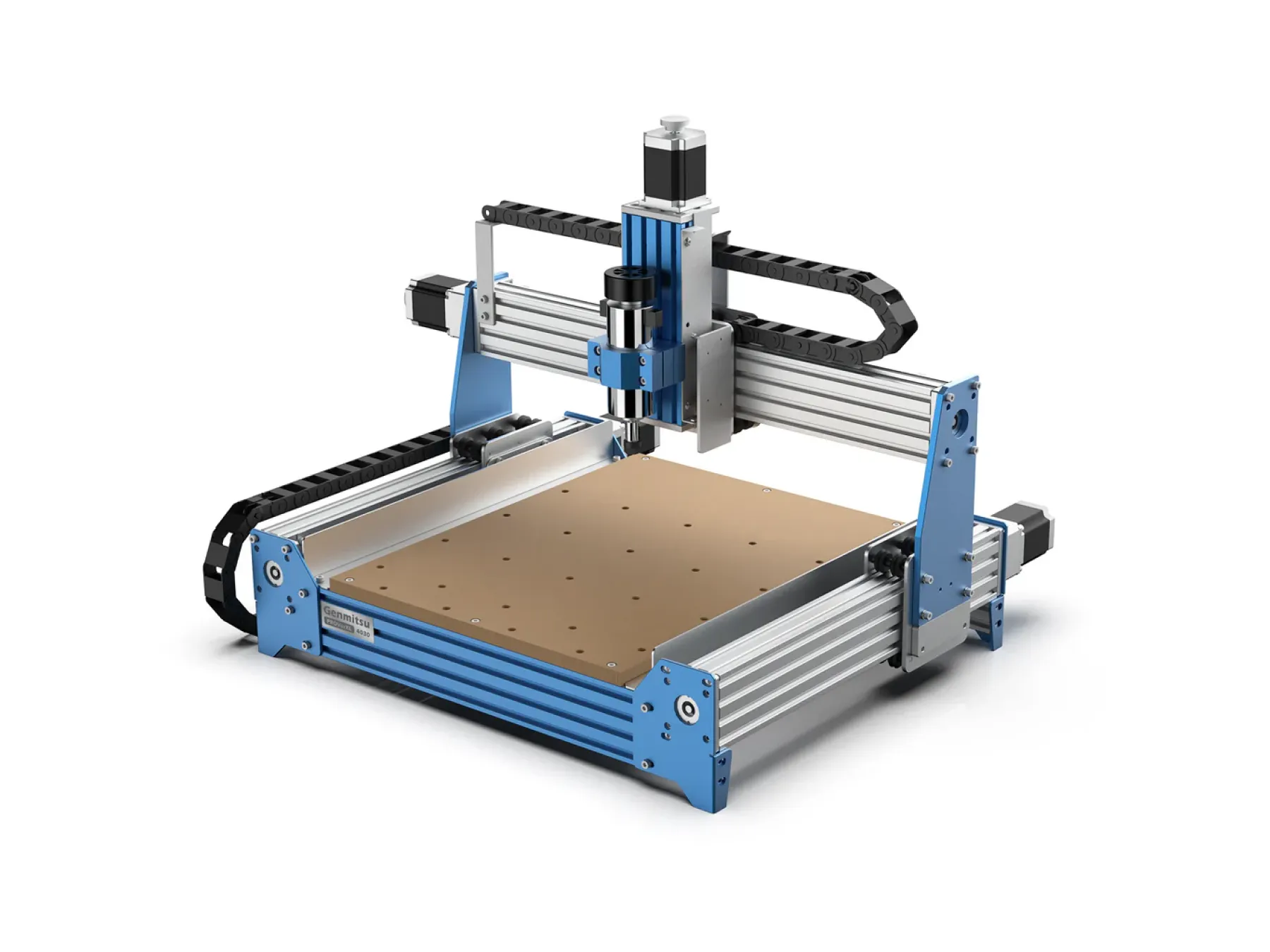

Desktop CNC machines are small-scale, computer-controlled tools designed to automate cutting, shaping, and carving processes on various materials. Unlike industrial CNC machines that often require dedicated floor space, power hookups, and thousands of dollars in investment, desktop models can fit on a workbench and plug into a standard outlet.

These machines are ideal for prototyping, light production, and educational use, thanks to their relatively low cost and minimal setup requirements. While they don’t match industrial systems in raw power or work area size, their flexibility makes them indispensable to many small-scale operations.

Common sizes range from 12x12 inches to 32x32 inches, with cutting capabilities suited for plastics, wood, foam, soft metals, and more.

Most common desktop CNC types:

- CNC mills – Precision-focused machines ideal for metals and plastics

- CNC routers – Great for wood, foam, and composite materials

- CNC lathes – Designed for symmetrical objects and turning operations

- CNC plasma cutters – For cutting sheet metal with high heat

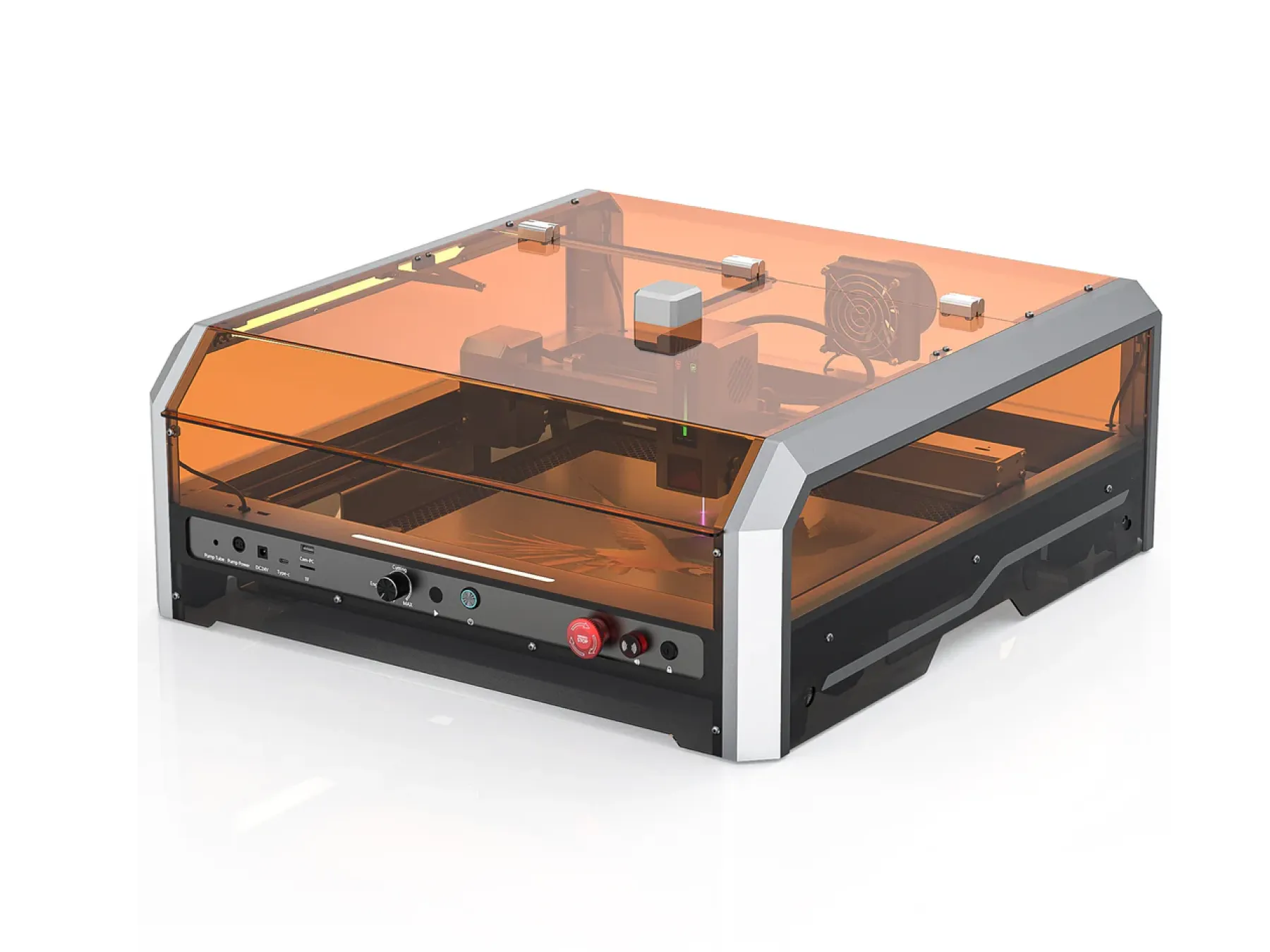

- Hybrid machines – Combine CNC with laser or 3D printing capabilities

How do desktop CNC machines work?

At their core, desktop CNC machines operate through subtractive manufacturing — starting with a solid block of material and precisely removing sections to create the desired shape. The process is orchestrated via computer software that controls the machine's motors, spindle, and movement systems.

Each part of the workflow builds upon the last, and even though the machines are smaller, they follow the same digital-to-physical path as industrial CNCs.

Key functional stages of desktop CNC machining:

- CAD design – The digital model is created in 2D or 3D

- CAM processing – Toolpaths are defined for how the machine will cut

- Toolpath generation – G-code instructions are generated

- Machine execution – The CNC machine follows commands to cut material

-

Post-processing – Final steps such as sanding, deburring, or finishing

What are the main components of a desktop CNC machine?

Understanding how a desktop CNC works means breaking it down to its parts. These components determine not only performance but also reliability and maintenance needs.

- Key parts of a typical desktop CNC:

- Stepper or servo motors – Provide precise movement in X, Y, Z axes

- Spindle/router – The cutting head; RPM and torque affect material compatibility

- Control board (e.g., GRBL, Mach3, proprietary) – Translates software instructions into motor commands

- Frame – The machine's skeleton, critical for rigidity and accuracy

- Rails/Lead screws/Ball screws – Enable smooth, repeatable motion

- Workholding surface – Options include T-slot beds, vacuum tables, or clamps

-

Emergency stop/safety switches – Essential for safe operation and quick shutdowns

Why are desktop CNCs becoming popular in rapid prototyping?

The appeal of desktop CNCs lies in their ability to combine hands-on iteration with digital control — a sweet spot for engineers and makers alike. Unlike 3D printers, which build layer by layer, CNCs create high-precision parts with stronger material integrity. And compared to industrial CNCs, they’re faster to learn and much more cost-effective.

- Advantages of desktop CNCs in prototyping:

- Shorter iteration cycles – Design, cut, test — all in the same day

- Localized production – No need to wait for outsourced machining

- Easy design testing – Create functional prototypes that match final-use conditions

- Tooling independence – No need for molds or special fixtures

-

Material variety – Work with woods, plastics, foams, and some metals

What industries are using desktop CNCs for prototyping today?

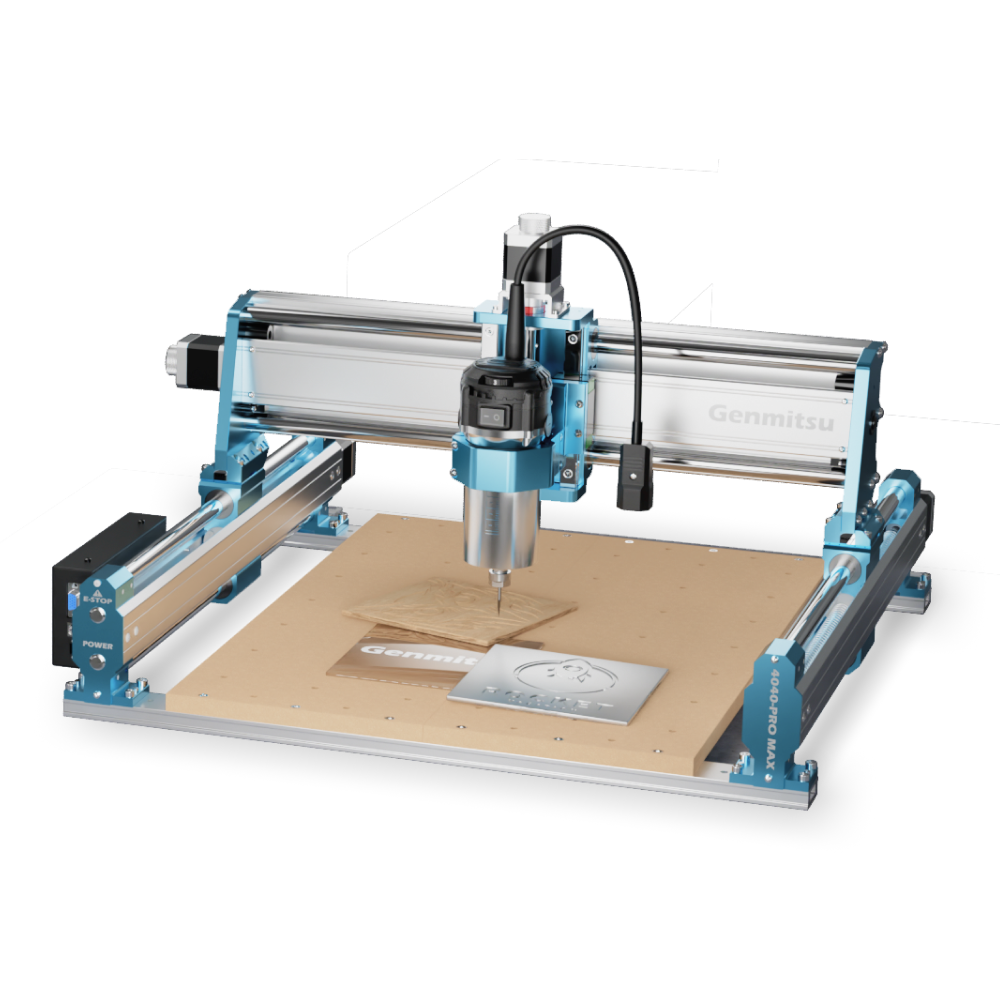

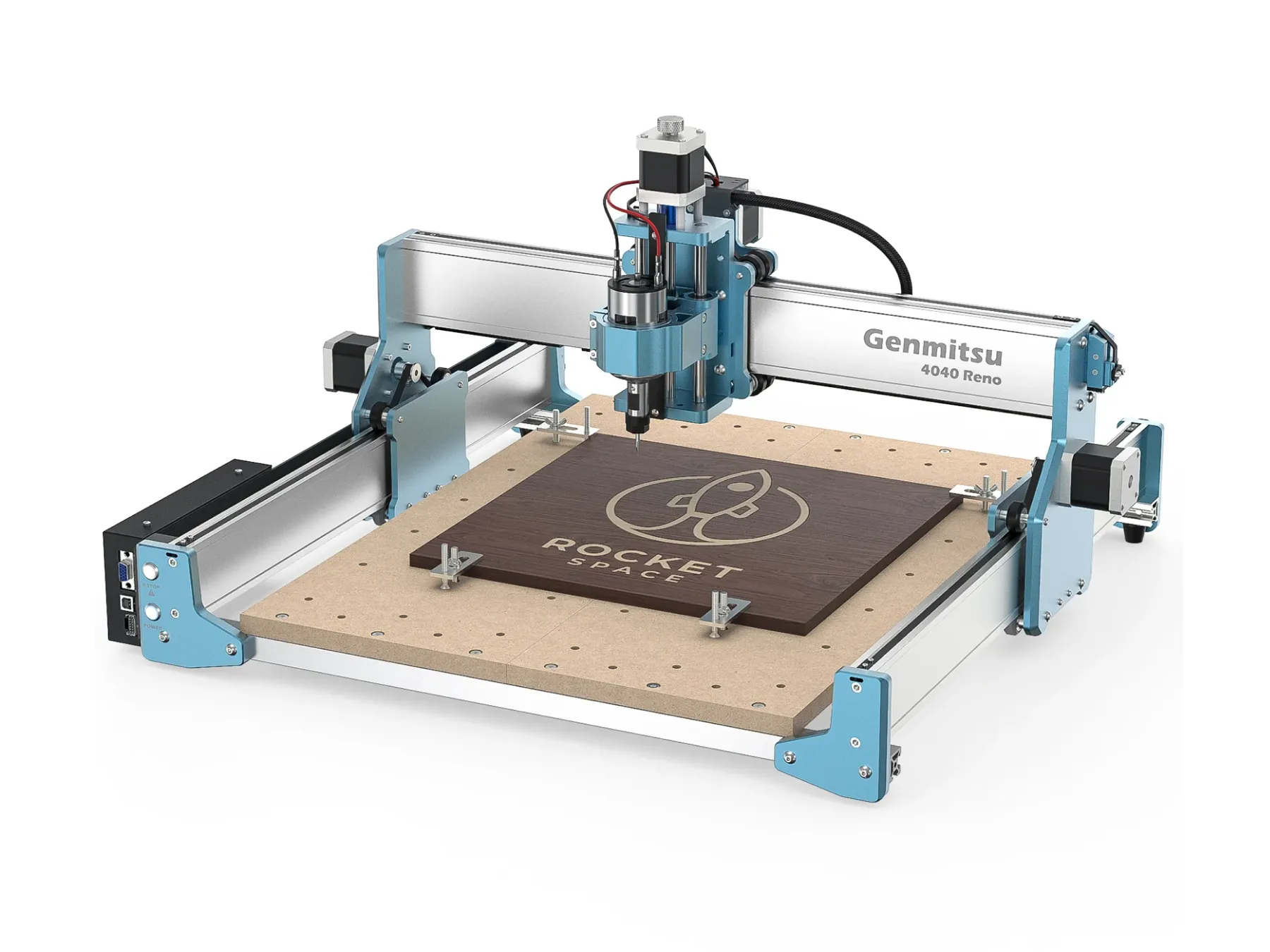

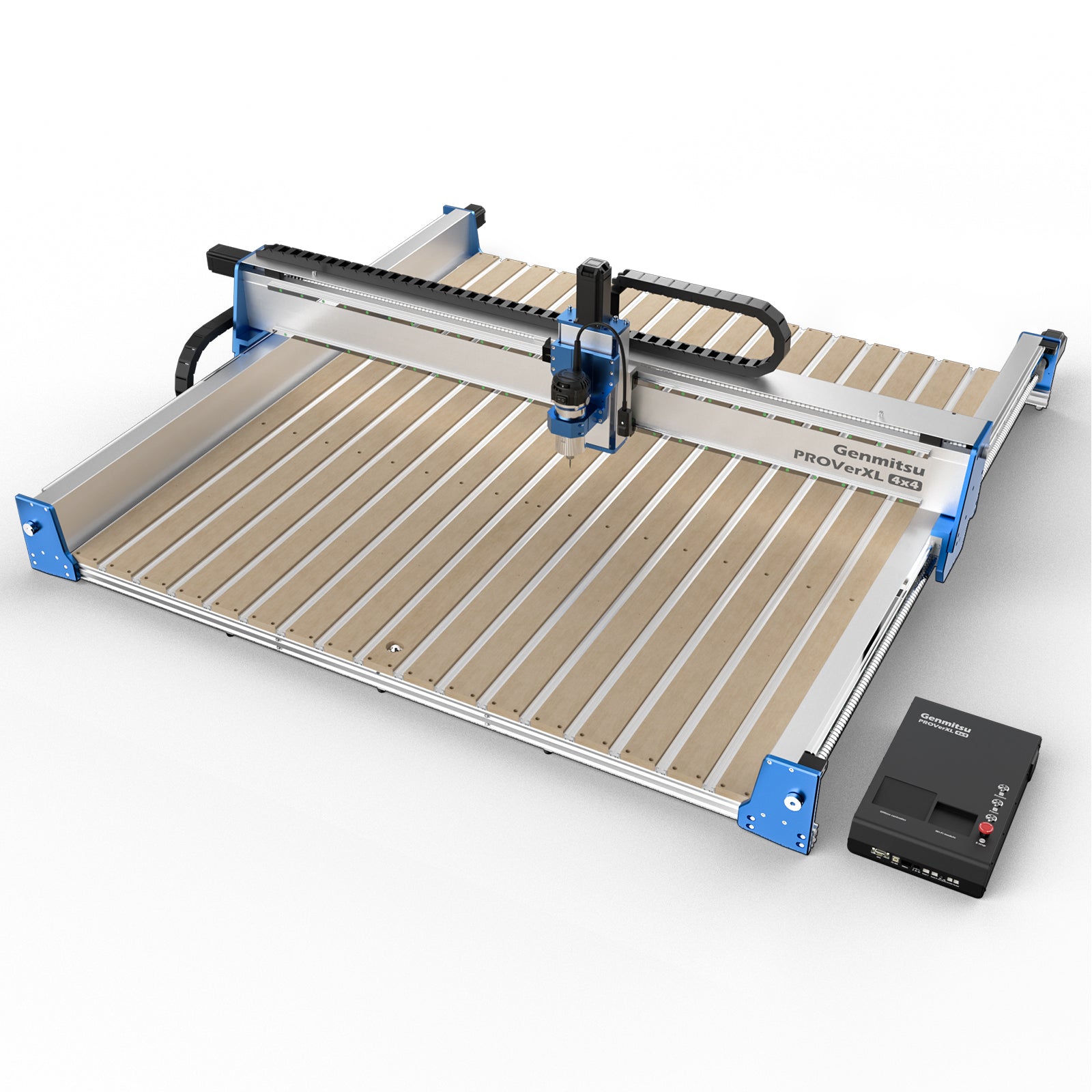

As machines like the Genmitsu CNC routers become more capable, industries are finding new ways to incorporate desktop CNCs into R&D workflows. From classrooms to startup garages, these machines are quietly driving innovation.

- Common industries and their use cases:

- Consumer electronics – Prototyping housings, enclosures, and mounts

- Aerospace – Lightweight brackets and aerodynamic test parts

- Automotive – Early-stage molds, brackets, and fluid housings

- Product design – Physical validation of ergonomic and mechanical ideas

- Education – Hands-on learning in engineering and design curriculums

- Jewelry – Wax carving and soft metal detailing

-

Robotics – Custom brackets, sensor mounts, and structural parts

What materials can you machine with desktop CNCs?

One of the core strengths of desktop CNCs is their material flexibility. While they can’t tackle hardened steel, they do excel at prototyping with lighter, more accessible materials — as long as the spindle and rigidity are up to the task.

Material options:

- Wood – Including softwoods, hardwoods, MDF, and plywood

- Plastics – ABS, acrylic, HDPE, Delrin for functional prototypes

- Aluminum – 6061 and 7075 grades (higher-end models only)

- Brass & Copper – Milled with slower feed rates and sharp tooling

- Foam – PU and polystyrene for concept models

-

Waxes – Perfect for lost-wax casting workflows

Machine rigidity, spindle speed, and bit selection are all crucial in determining what materials you can successfully cut.

What are the limitations of desktop CNCs in prototyping?

Despite their versatility, desktop CNCs come with trade-offs. Their compact size and affordability often mean compromises in power, speed, and part precision — especially when compared to full-sized industrial counterparts.

Key limitations:

-

Limited travel (bed size) – Restricts part dimensions

-

Lower spindle power – Struggles with metals or dense materials

-

Material compatibility – Not all plastics or metals are machinable

-

Surface finish and vibration – Lightweight frames can cause chatter

-

Manual tool changes – Adds downtime during multi-tool jobs

-

Not suited for large batch production – Ideal for prototyping, not scale

What are typical tolerances for desktop CNC machining?

Desktop machines have come a long way in precision, especially when cutting soft materials. However, tolerances still depend heavily on machine rigidity, bit quality, and setup.

Real-world tolerances:

-

±0.05 mm – Achievable with high-end units on plastics or wood

-

±0.1–0.2 mm – Typical for entry-level or budget models

What affects tolerance:

-

Tool wear and bit sharpness

-

Material hardness and consistency

-

Frame rigidity and vibration damping

-

G-code optimization and cut depth per pass

What software is used with desktop CNC machines?

The digital-to-physical workflow relies on a stack of software tools, from designing to executing the job. Thankfully, most desktop CNC ecosystems support a wide range of open-source and commercial options.

Common software tools:

-

CAD: Fusion 360, SolidWorks, FreeCAD

-

CAM: Fusion 360 CAM, Carbide Create, VCarve

-

Controller: GRBL, Mach3, LinuxCNC

-

G-code senders: UGS, Candle, bCNC

What are the steps to go from design to prototype using a desktop CNC?

Turning a concept into a physical part follows a clear workflow, which becomes second nature after a few projects.

Steps:

1. Create or import your model in CAD

2. Define tools and toolpaths in CAM

3. Set material dimensions and stock placement

4. Export G-code and load into controller software

5. Mount material and insert cutting tool

6. Run job under supervision

7. Finish part via sanding, cleaning, or painting

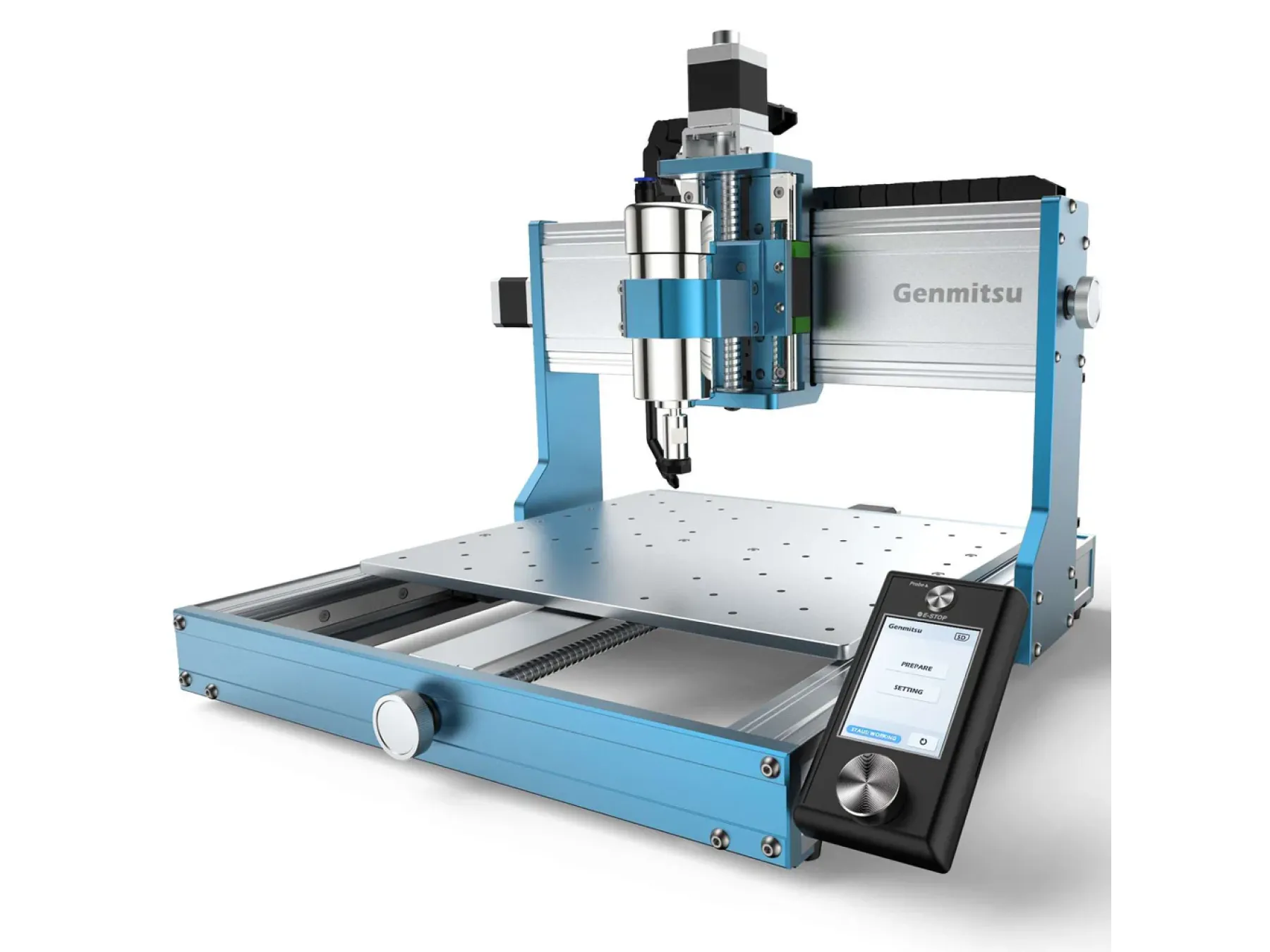

What makes a great desktop CNC machine for prototyping?

Not all machines are built equal. When choosing one for prototyping, certain features will significantly affect results and usability.

Key buying criteria:

-

Rigid frame – Prefer aluminum or steel over plastic

-

High spindle speed – 15,000+ RPM for cleaner cuts

-

Ball screws over lead screws – For accuracy and backlash reduction

-

Software compatibility – Open ecosystems are easier to scale

-

Expandability – Add-ons like dust collection, rotary axes

-

Community support – Active forums, tutorials, and part libraries

How do desktop CNCs compare with 3D printers for prototyping?

While often compared, these two tools excel in different areas. Choosing one depends on project needs.

CNC vs. 3D printing:

-

Material strength: CNC wins with solid blocks

-

Speed: 3D printing is faster on simple, hollow forms

-

Post-processing: CNC parts need less finishing

-

Material cost: 3D filament is cheaper than some CNC stock

-

Design freedom: 3D printing handles complex geometries better

-

Accuracy: Comparable — both can hit ±0.1 mm with tuning

Conclusion

Desktop CNCs are no longer just tools for hobbyists. They're becoming a vital part of modern prototyping — bridging the gap between weekend projects and full-scale production. As machines like the Genmitsu CNC router become more refined, they offer a powerful combination of accessibility, precision, and speed.

Whether you're designing a drone frame, a gear housing, or a test rig, desktop CNCs give you the tools to move fast, test ideas, and bring functional prototypes to life — right from your bench.